|

Building and Construction MaterialsBuilding and construction materials manufactured in

KwaZulu-Natal include paving, kerbs, decor, tubes, pipes

and fittings, bricks, blocks, etc. The estimate of the

tonnage of different commodities is made difficult by the

wide range of products incorporated in this sector. These

products include tools, gypsum, paint, glass, wood,

particle board, electrical fittings, doors, windows,

structural steel, reinforcing steel, plastics, textiles,

ready-mixed concrete, sand, stone, and building cement and

lime.

The size of the South African construction market in 2004

was estimated at R 100 billion. The main contributors to

total income were construction of buildings with R33.1

billion (33,0%), of civil engineering

structures with R27.4 billion (27,4%), other building

completions with R10.6 billion (10,6%), and other building

installations with R8.9 billion (8,9%).

If investment targets are achieved, this sector could

double in size over the next decade. The estimated

production capacity in South Africa, including its Customs

Union partners, was 13.0-13.5 million tons in 2004.

South Africa's cement and building supplies industries

have geared up for the expected construction boom, with

new projects worth around R4.0 billion announced in 2005

and further projects in 2006-2007.

|

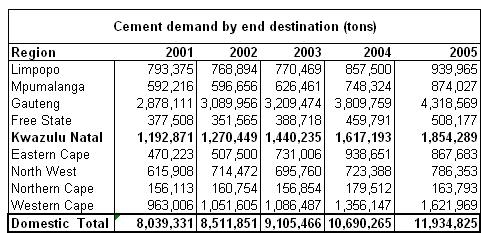

CementIn 2005, the demand for cement was estimated at 11,9

million tons of which KwaZulu-Natal was responsible for

1,8 million tons. All South Africa's major cement

producers have begun importing to meet increasing

demand as a result of the wide range of capital projects

scheduled for completion before 2010. These include 5

major new stadiums and 5 stadium upgrades along with other

projects. Cement sales for March 2007 increased to 1,374

million tons from 1,18 million tons for the same period

in 2006. Based on these statistics, it can be estimated

that cement sales for 2007 could be approximately 16

million tons.

|

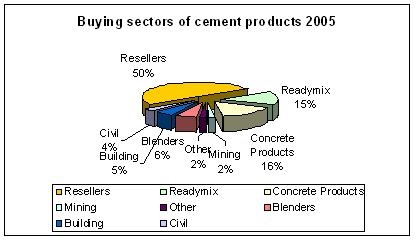

The proportion of cement sales by sector is shown in the

above graph for 2005. South Africa’s

4 cement companies together operate 11 cement factories

that have been continuously expanded to meet the local

demand over the last 50 years. The main cement plants in

KwaZulu-Natal are at Durban (Coedmore area) and Newcastle

with current capacity of about 1 million tons per year.

Announcements of capacity expansion totalling 3,3 million

tons p.a. (including refurbished capacity) at the various

factories will raise the total South African industry

capacity to about 16,5 million tons per annum. The demand

forecasts

indicate that this capacity will be sufficient to satisfy

expected growth to the end of 2012. In 2006/2007, the

import of cement and clinker through South African

ports was estimated at 891,012 tons.

The total market share of ready-mixed concrete has grown

from 13,9% to 15,5% in 2005 (based on cement sales),which

is 20% growth for two consecutive years.

There are numbers of manufacturers of precast concrete

products in the province, all of which use only road

transport for their products. StoneAggregate is produced in or near most cities and towns in

South Africa. Crushed stone, sand and gravel are most

often used by the construction industry. Industrial sand

and gravels are used for purposes such as foundry

operations, glass manufacturing, abrasives and filtration

beds of water-treatment facilities, as a source of calcium

in fertilisers, as a metallurgic fluxstone, and as

filtration systems.

Aggregates make up 70% or 80% of the volume of

concrete, and the aggregates used in asphalt mixtures

(roadways – hot-mix asphalt, cold-mix asphalt,

surface treatments) comprise approximately 95% of the mix

mass.

Aggregates include crushed stone, sand and gravel, and are

the most abundant natural resource available. They are

used

as a primary raw material component in construction,

agriculture and other chemical and metallurgic industries.

The domestic availability of aggregate and sand, which is

ultimately linked to cement sales, is expected to

increase from 114.1 million tons in 2007 to 120.2 million

tons in 2010, representing an annual average growth rate

of

1.75% and to continue with the growth trend to 134.2

million tons by 2016, an annual average increase of 3.16%

between 2012 and 2016.

Dolerite Quarry

|

SteelSteel used in the building, construction and mining

sectors accounts for about 25% of local consumption. It is

comprised primarily of prefabricated profiles and sections

used in industrial building systems, civil structures

and concrete reinforcing bar. Global carbon steel

consumption reached a milestone of over one billion tons

in 2005, driven by extraordinary growth, primarily in

China. South Africa accounts for about 0,5% of global

steel consumption. Both globally and locally the steel

market is subject to business cycles linked to economic

growth patterns and steel price trends.

Per capita steel consumption in South Africa is roughly

half the world average (90 kg vs 170 kg). South African

per

capita consumption is similar to countries

such as Brazil (100 kg) and Egypt (75 kg), and

substantially above India (30 kg). Consumption of primary

carbon steel products has been fluctuating at levels of

between 4 - 4,5 million tons annually. In 2006/2007 the

port of Richards Bay exported 298,456 tons of steel, and

Durban 1,287,356 tons.

Local sales of primary carbon steel products in South

Africa in 2006 was an estimated 5,3 million tons. The

range of primary carbon steel products and semi-finished

products manufactured in South Africa includes: billets;

blooms; slabs; forgings; light, medium and heavy sections

and bars; reinforcing bar; railway track material; wire

rod; seamless tubes; plates; hot- and cold-rolled coils

and sheets; electrolytic galvanised coils and sheets;

tinplate; and pre-painted coils and sheets. BricksThe combined annual manufacturing capacity of the SA clay

brick industry is estimated to be in excess of 3,5 billion

bricks. It is estimated that 75% of all bricks used for

buildings are genuine clay bricks.

Bricks are made in a number of different places in KZN

including Durban, Pietermaritzburg, Newcastle and

Empangeni-Richards Bay. PaintsThere are several large paint factories in the Durban

area,

supplying more than 50,000 tons of products per annum by

road to the building trade all over South Africa. Inputs

include titanium, resins, solvents and other pigments. Building MaterialsThere are numbers of firms supplying building materials in

KZN that are branches of manufacturers in Gauteng, and

receive all their products for local distribution on

road .These include pipes, roofing, guttering, beams,

ceiling board, fascia boards, roof tiles, doors, windows,

panelling, plastic pipe, brass plumbing fittings and glass. Transport of Building ProductsThe vehicle configuration used for the transportation of

various building supplies ranges from rigids (8 ton) to

articulated combinations, some with draw-bar trailers and

interlinks. The vehicle type and size vary with the

commodity and the distance that it is to be transported,

as well as the method of load handling and the access to

the load and unload points.

The vehicle types used for building and construction

materials range from ready-mixed concrete mixers to

flatdecks, flatdecks with dropsides, tippers, etc.

For bricks the trend has been towards palletised and

shrink-

wrapped modular loads that can be loaded and unloaded by

on-board crane.

The bulk of the finished cement products is distributed

through the retail trade (resellers), and is ultimately

used by small to medium-sized builders, emerging

contractors and DIY users.

|

|