|

ForestryCommercial plantation forestry in South Africa encompasses

large planted forests established to supply raw

materials to satisfy mining, construction and industrial

markets. The forests supply pulp mills, sawmills and

factories which process the raw materials. Wood is a key

raw material to which value is added in many industries

such as: mining; construction of houses and

commercial buildings; poles for electricity distribution

and telecommunications; furniture manufacture; pulp and

paper manufacture; and energy production. LocationThe timber growing areas in KwaZulu-Natal are divided into

5 main afforestation regions which are identified as

Northern Natal, Midlands, Southern Natal, Zululand, and

Maputaland. SpeciesThe main species planted in South Africa are pine (52,2%)

eucalyptus (38,92%) and wattle (8,3%). All of these are

grown in KZN. The dominant form of timber produced is

roundwood that is used for chipping for export. Mainly

hardwood species are used for this purpose.

Maturing Pine

|

The regions with the largest hardwood areas are the

provinces of KwaZulu-Natal (Midlands) and Mpumalanga

South where 49.2% of all hardwoods occur. The dominant

species is eucalyptus grandis which accounts for 51.8% of

the total hardwood area. South African hardwoods are grown

primarily for pulpwood and mining timber production on an

eight to twelve year rotation. Pulpwood is the raw

material for newsprint and kraft paper production.

Softwoods consist mainly of pine species; about 69% of all

softwoods are for sawlog production.

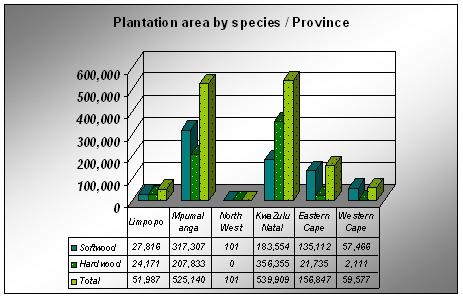

KwaZulu-Natal accounted for 356,355 hectares of hardwood

and 183,554 hectares softwood in 2005.

|

Mature pine, which is becoming increasingly scarce, is

usually reserved for saw-milling due to the high value of

the product (approximately R 500,000 per hectare). It is

noteworthy that the tonnage of sawn timber imported is

rising each year due to the shortage of local supply, and

it is predicted that South Africa will be almost totally

dependent on imports for most sawn timber within the next

ten years. ExtentThe forestry industry in KwaZulu-Natal covers about

740,000 hectares (8.2% of the total area of the province)

with 560,000 hectares already planted

and a further 190,000 hectares of land owned by forestry

organisations unplanted.

A comparison, by province, of the 2004/05 plantation

area is given in the table below.

The reduction in the area under forests is a matter for

concern as the future demand for timber will be

increasingly under-supplied.

Forestry Midlands

|

ValueThe GGP of KZN amounts to about R 57 billion of

which forestry contributes approximately R6.0 billion

(10.7%) through forest products and a further 1.5% through

forestry .

The forestry industry has a capital investment in KwaZulu-

Natal of R14 billion of which R10 billion is in timber

processing and R4 billion in plantations.

The industry is one of the province's largest employers,

absorbing about 43 000 people of the total 2.8 million

labour force. The industry pays R662 million per annum to

staff, and it is estimated that 250 000 people in the

province are in some way dependent on the industry .

If timber processing were to be added to the above figures,

the total impact on employment in the province could be

doubled.

There are currently 10 000 small growers in KZN with an

area of 14 000 hectares under timber and a current

investment of R30 million from which they earn R24 million

per annum. The small grower population is being encouraged

through schemes such as Forests Project ,Grow, Forests

Khulanathi Scheme and the SA Wattle Growers' Union scheme,

which are adding about 2000 new small growers and 3000

hectares each year .

Eucalyptus Plantation

|

From the national perspective the KZN timber industry is

of great importance as 38% of all plantations

and 45% of all new afforestation are in KZN . Nationally,

40% of total plantation output comes from KZN, the wattle

industry is focused in KZN, and 56% of all pulpwood is

produced in the province.

The total roundwood intake during the year 2004/05

was 23 929 382 m³ compared to 22 553 020 m³ in

2003/04.

The value of sales of timber products equalled R15 025

million in 2004/05 compared to R14 815 million for 2003/04.

In 2005, KwaZulu-Natal produced 7,7 million m³ of

hardwood and 2,6 million m³ of softwood. SynergyIn addition to the timber and forestry interests, there

are

also exporters of wattle extract and charcoal from the

Kranskop-Sevenoaks areas which are users of rail and road

for container transport to the port of Durban. Relative importance55% of all timber used in South Africa is processed in KZN

and, of the 13 pulp, paper and board processing plants in

South Africa, 10 are located in KZN. Other industries

that

are significant in KZN due to the presence of the forestry

industry are:

* 2nd largest pulp and paper mill in SA (Richards Bay)

* 2nd largest newsprint mill in SA(Durban)

* world's largest producer of rayon pulp (Umkomaas)

* largest hardboard plant in SA (Estcourt)

* the only 2 SA woodchip export plants (Richards

Bay)

* the 2 largest SA producers of wattle extract

(Hermannsburg and Dalton)

* the 2 largest SA producers of charcoal for export

and local consumption (Dalton-Greytown).

Import-Export VolumesThe KZN forestry industry is a major source of road and

rail freight as well as contributing a significant export

tonnage through the ports of KwaZulu-Natal. Eucalyptus timber and wattle are exported in the form of

woodchips. Wattle timber is used for the manufacture of

pulp. Other important activities are the production of

charcoal and firewood. There are only four woodchip export

facilities in South Africa, three of which are situated in

Richards Bay and one at the port of Durban. According to

the National Port Authority export statistics for 2006/07,

3,728,948 tons of woodchips, 37,641 tons of woodpulp and

83,281 tons of paper-related products were exported

through

the port of Richards Bay.

The woodchipping mill facility located at Maydon Wharf in

the Port of Durban has a capacity of 360,000 air dry

tons of hardwood chips per annum. This woodchip facility

is aimed at the export of eucalyptus hardwood chips from

Durban to pulp and paper manufacturers in Japan. The mill

consists of a totally enclosed woodchip storage shed that

holds 244,000 cubic metres or 80,000 tons of woodchips.

It also features two log decks and two-22 metre, 60-ton

weighbridges for road vehicles and a 100-ton rail

weighbridge. The debarked 2,4 m logs arrive at the plant

via rail and truck where they are fed into an imported

Camura-Metso chipper. A conveyor belt moves the woodchips

to the storage shed with a capacity of 80,000 tons. The

woodchips are conveyed to a ship loader fitted with a jet-

slinger that evenly sprays the chips into the hold. It

takes about four days to load a ship.

In 2006/07 226,716 tons of woodpulp and 395,900 tons of

woodchips were exported through the port of Durban, and in

the first 8 months of 2007 the Durban terminal exported

one million tons of wood chips to Japan.

It should be noted that 68,921 tons of woodpulp were also

imported through Durban in the same year. The bulk of the

timber which comes into South Africa is breakbulk sawn

timber, and 68,921 tons were imported through Durban

harbour in 2006.

The volume transported on the land modes (road and

rail) to processing plants and exported through the ports

is estimated at approximately 10 million tons per annum in

the form of timber and timber-related products, paper,

woodchips,

etc.

Approximately 1,4 million tons of timber are transported

via rail on the KZN branch lines and onto the main lines.

Approximately 108,045 tons of timber are also railed from

Swaziland to Richards Bay on the Durban-Empangeni-Golela

and Swaziland line.

The largest proportion of timber is transported by road

to various processing plants, mills and for export. The

vehicles used are flatdecks with steel stakes or

purpose-designed, stake-sided trailers with the vehicle

configurations of all groups from 5-40 ton

carrying capacity.

Timber on Rail

|

|

|