|

Meat Processing and DistributionThe consumption of chicken meat is on the increase in

South Africa and is bigger than the total consumption of

red meat; a trend that is likely to continue. [Broiler

poultry production is discussed elsewhere in this Freight

Transport Databank, under the Poultry industry].

The red meat industry remains one of the most important

agricultural sub-sectors in South Africa, but has come

under increasing pressure in the period following

deregulation. This is mainly due to;

(i) declining per capita demand for red meat,

(ii) increased competition from overseas producers,

Southern African Development Community (SADC)countries,

Namibia and Botswana, and

(iii) institutional challenges.

Almost 60% of cattle in South Africa are finished for

slaughter in feedlots (confined areas with watering and

feeding facilities where livestock are fed grains and

concentrates to produce consistent meat quality). The other

40% of beef cattle are raised on natural grassland.

Some of the largest feedlots in KZN are situated in the

Cato Ridge, Cramond and Vryheid areas. South African

feedlots normally buy weaner calves with a live mass of

230 kg at an age of 205 days, and add 105 kg carcass mass

through extensive feeding for about 100 days, eventually

slaughtering an animal at approximately 215 kg carcass

weight. The weights vary according the age and breed of

cattle. When animals are ready for the market, they are

transported from the farm or feedlots to the abattoir by

road. The transportation of live cattle is governed by the

transportation welfare codes, known as LWCC (Livestock

Welfare Coordinating Committee).

Feedlot

|

The abattoir is a key transformation area in the South

African meat supply chain. The abattoir industry is

responsible for the conversion of livestock to meat or

carcasses. Processing plants or meat manufacturers consist

generally of two types of production cycles - the canned

meat and/or the fresh meat cycle. The cuts have to be under

constant cooling, and therefore the loading takes place in

an area that is totally sealed off to ensure the products

do not come in contact with hot air. All frozen products

are kept at a temperature of -18ºC”. If the cold

chain is interrupted, the shelf live of products is

significantly reduced. Below is a diagram illustrating the

red meat industry.

The livestock population in KwaZulu-Natal at the end of

2005 was as follows:

cattle 2,857,000, sheep 775,000 and pigs 164,000. In KwaZulu-Natal, the number of registered abattoirs

stands at approximately 49 (see table below), which

constitutes approximately 10% of all those in South Africa.

Following the recent deregulation of the South African

meat industry, a number of the larger feedlots have now

vertically integrated into processing, wholesaling and

even retailing their own quality beef products. The grades

of abattoirs varies from an A grade where over 100 cattle

are slaughtered a day to grade F, where fewer that 4 cattle

per day are slaughtered.

|

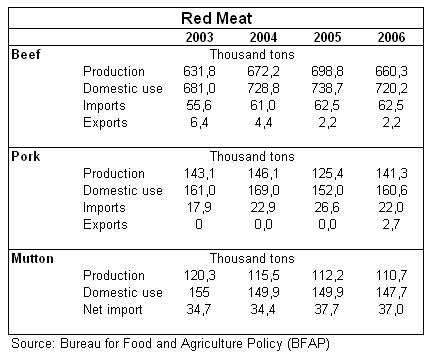

South Africa, as is evident from the table above,

consumes more than it produces. In 2006 South Africa

produced 660,300 tons of beef of which 720,200 tons were

consumed; pork production was 141,300 tons of which 160,600

tons were consumed, mutton production was 110,700 tons of

which 147,700 tons were consumed.

South Africa is an importer of beef (62,500 tons),

mutton (37,000 tons) and pork (22,000 tons) as indicated in

the table. Beef is mainly imported from SACU countries

(Namibia,

Botswana, Swaziland and Lesotho) and also from Argentina,

Paraguay, Australia, Zimbabwe, Brazil, Uruguay and New

Zealand.

South Africa is a net importer of lower

grade meat, mostly for the processing sector, while it

exports some higher grade cuts to specific niche’

world

markets to realise above-average rate of returns.

South Africa exported 2,200 tons of beef mainly to Angola,

Germany, Great Britain, Greece, Lebanon, Mozambique,

Norway, Reunion and Swaziland. One of the large abattoirs situated in Ladysmith produces

approximately 65,000 tons of red meat, which is

distributed predominantly in Northern KwaZulu-Natal. The

cattle and sheep are transported by road from areas in the

Free State such as Harrismith, Bethlehem and Vrede to the

abattoir. Approximately 4,500 tons of mutton is produced

in KwaZulu-Natal, which indicates that it is not self

sufficient to meet its domestic demand, therefore 37,000

tons of mutton is imported from the rest of the world

through Durban harbour to meet the demand in KwaZulu-

Natal, Mpumalanga and Gauteng.

KwaZulu-Natal, Limpopo and Gauteng are self-sufficient in

the production of pork. Excess production in KwaZulu-Natal

is supplied to the Northern Cape, Free State and

Mpumalanga. Imports entering through the port of Durban

are supplied to Mpumalanga. Transport in the meat industryTransport in the meat industry is entirely by

road, using vehicles of appropriate configurations for the

cargo carried. Cattle are transported in open carriers,

pigs tend be transported on flat-bed, gate-sided,

open vehicles, and sheep are transported in purpose-made,

triple-deck, livestock carriers. When livestock are ready

for the market, the animals are transported from the

producer (farmer) or feedlots to the abattoir. Once

slaughtered, meat is stored in refrigerated cold stores

and the carcasses are transported from the abattoir in

refrigerated vehicles for distribution to

butcheries, wholesalers and retailers, and by direct

delivery to hotels, restaurants and other hospitality

establishments.

Based on the production figures for cattle, an estimated

2,4 million cattle 5,2 million sheep and 2 million

pigs were transported to various abattoirs in South Africa

to be slaughtered, which amounts to in excess of 900,000

tons on the road network. If one includes the imports of

beef, mutton and pork, approximately 1 million tons of red

meat is being transported to various markets within South

Africa.

The supermarkets also play an important role in the

distribution of beef products to the countrywide consumer

market. Although insulated, the vehicles used are not

permitted to travel on gravel roads for fear of

contaminating the product, which will amount to huge

losses.

|

|