|

Port of Richards Bay

Loading of coal at Richards Bay

|

IntroductionA number of factors contributed to the development of Port

of Richards Bay in the 1970s. It had become urgent to

provide additional rail links between the coast and the

mining heartland of the country. It was also necessary to

provide a deepwater port to accommodate the new large bulk

carriers. From three possible sites for a new harbour, the

choice fell on Richards Bay for five important reasons:

the large lagoon; the ease of dredging; direct link with

the national rail network; an adjacent town, Empangeni, to

stimulate initial development; and ample fresh water.

In May 1972, parliament authorised the construction of the

harbour in Richards Bay, and on 1 April 1976 the first

phase of the harbour was officially opened. Built for the

export of coal, it has since expanded into other bulk and

breakbulk cargoes. Richards Bay is South Africa’s

premier

bulk port and the most modern. In 2005 the port handled 89

million tons of cargo. Richards Bay handles in excess of

80 million tons annually, representing 55% of South

Africa’s seaborne cargo. This makes it the

country’s largest

port in terms of volumes handled.

Richards Bay serves the coalfields of KwaZulu-Natal and

Mpumalanga as well as timber and granite exporters from as

far away as the Eastern Cape and Northern Cape. The port

is now handling an increasing variety of bulk and neobulk

cargo in addition to breakbulk. Much of the general cargo

has migrated away from Durban in recent years. Exports

remain the main activity of the port. Port LayoutSituated at longitude 32º 02' E and latitude 28º

48' S,

Richards Bay, South Africa's most northern and

easterly port, is 87 nautical miles (160 km) northeast of

Durban and 252 nautical miles (465 km) southwest of

Maputo. The port occupies 2,157 ha of land area and 1,495

ha of water area, but has the potential to expand when

required, making it potentially one of the largest ports

in the world. The entrance channel is dredged to a

permissible draught of 17,5m with a -19,5m depth in the

entrance channel.

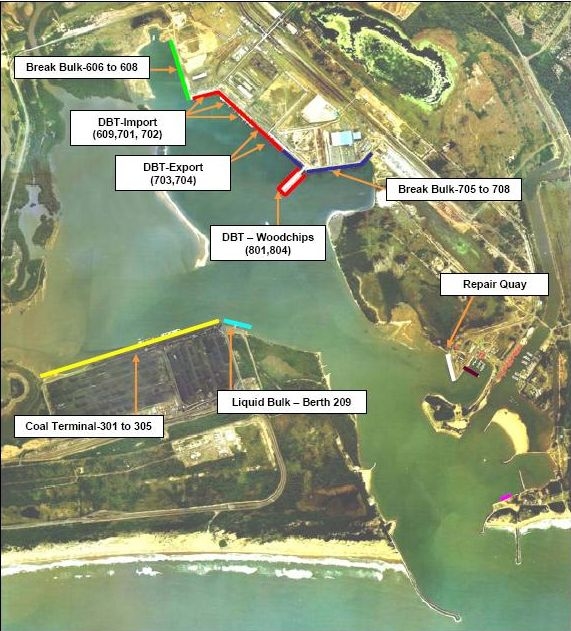

Aerial layout view of Port of Richards Bay

|

The outer anchorage is situated approximately 3-5 nautical

miles south-east of the port entrance. An inner anchorage

is available for emergency use only.

The anchorage immediately to the north of the harbour

entrance channel is a

prohibited area due to the location of an offshore

pipeline.

Pilotage is compulsory for all vessels, and there is a

fleet of five tugs owned and operated by the Transnet

National Ports Authority (TNPA).

Berthing depth varies between 8m (small craft berth) and

19m (coal berths). DocumentationImmigration

Two Crew Lists

Customs

Two Crew Lists

One Ships Store List

List of Narcotics

One Customs DA5 form

One Declaration of crew's personal effects

Load line/Safety Radio/Equipment Cert

Port Health

One Vaccinations List

One Crew List

One Maritime Declaration of Health

Ships Agency

Two Crew Lists

One copy of Ship’s Register

One copy of International Tonnage Certificate (1969)

One copy of International Safety Management

Certificate Port Facilities:Berth Lengths and Draughts

All berths are fitted with fenders. Berthing gangs are

provided by Transnet National Ports Authority, and the use

of this service, is compulsory. There are at present 21

berths in

service, including those at the privately operated

Richards

Bay Coal Terminal but excluding the dredger and tug

berths. An additional coal berth is currently under

construction.

The port of Richards Bay contains a dry bulk terminal, a

multi-purpose terminal and the privately operated coal

terminal. Other private operators within the port include

several wood chip export terminals and a bulk liquid

terminal. The port has extensive rail and conveyor belt

systems servicing the berths from nearby factories and

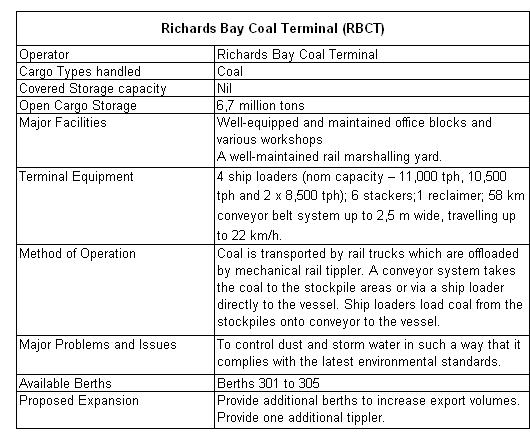

plants. Richards Bay Coal Terminal (RBCT)

During its 2005 financial year the Richards Bay Coal

Terminal (RBCT) handled 68,35 million tons of export coal,

an increase of 2,3% on the previous year (66,83m in 2004).

The terminal is currently undergoing a refurbishment to

increase its capacity to 92 million tons annually. Ships

are handled at four berths (301-304), each 350m in length

with a -19m water depth alongside and a permissible

draught of 17.5m. The adjacent 209 chemical berth is 300m

long and has a depth alongside of -14m with a permissible

draught of 12.5m.

Trains with an average payload of 16,800 tons on 200

wagons deliver coal to RBCT in a continuous process that

sees 30-35 trains per day arrive at the terminal.

A maximum of 6 million tons of coal can be stockpiled at

the

terminal. There are 80km of rail track within the RBCT

complex. The terminal has handled well in excess of 1

billion tons of coal for export since opening. The coal

terminal at Richards Bay has four ship loaders, two of

which have a nominal loading rate of 8,500 t/h, one with a

rate of 10,000 t/h, and the fourth with a rate of 11,000

t/h. By ratio, it is conceivable that RBCT can at this

stage achieve a total throughput of 77 million tons.

|

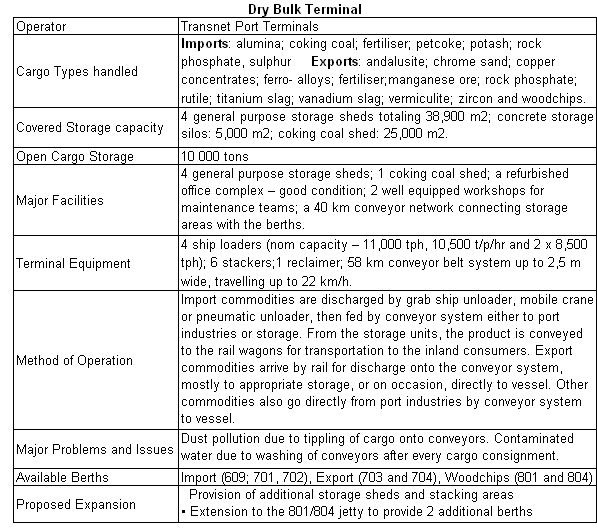

Richards Bay Dry Bulk Terminal

The terminal has the use of three import and five

export berths. Total throughput capacity is 18 million

tons per annum. Extensive use is made of multiple use

conveyor systems which require thorough cleaning after

each commodity. The terminal currently handles about 12

million tons of dry bulk cargo annually for import and

export, consisting mainly of ores and mineral cargo.

In 2005/2006, the Woodchip Terminal, which is situated at

berths 801 and 804, exported 4.6 million tons at an

average berth occupancy of 65 %. A high-volume woodchip

loader commissioned in 2004 has made this terminal one of

the world’s best and most efficient woodchip loading

facilities. The general export berths (703,704) handled a

combined total of 2.8 million tons during the 2005/2006

financial year. During this period, an average physical

berth occupancy of 70 % was achieved. The throughput

capacity of the terminal has been upgraded from 11 to 18

million tons per annum. The land surface area is 60,2

hectares.

|

Richards Bay MPT

The Richards Bay Multi-Purpose Terminal is the product

of the merging of two

separate terminals, namely the Bulk Metal and Combi

terminals. The resultant

integration of infrastructure and facilities has enhanced

the terminal’s ability to

manage a variety of cargo types, namely breakbulk, neobulk

and containers. The MPT terminal operates 24 hours a day

and is open for 363 days a year. The multi-purpose

terminal specialises in raw and semi-processed materials

such as steel, ferro-alloys and forest products. The

terminal currently operates across seven berths in the

port. The terminal has a throughput capacity of 5,6

million tons per annum and covers a land surface area of

62,2 hectares.The terminal has extensive warehousing and

covered storage areas for sensitive cargo, and a huge open

storage area comprising 330,000m² for cargo

handling. A

specialised 75,000m² ferro-alloy handling facility is

available.

In 2005/2006, berths 705 to 708 handled a total of 3.9

million tons, with an average occupancy factor of 70 %.

These volumes were made up of forest products, aluminium,

ferro metals, pig iron, bagged cargo and containers. The

port of Richards Bay presently handles small volumes of

containers (approximately 5,179 TEUs per annum), which are

handled through berths 706 to 708 by means of ship’s

gear

and mobile cranes. These berths are considered to have

reached their capacity based on present operations (950

000 tons per berth). In comparison, berths 606 to 608

handled 1.1 million tons of breakbulk cargo (scrap metal,

granite and ferro-chrome) in 2005/2006. The average berth

occupancy was 50%. Berths

K 606,607 & 608 - permissible draft 13,5m

K 705 - permissible draft 17,5m

K 706, 707 & 708 - permissible draft 13,5m

Commodities/Cargoes

• Ferro-alloys • Steel • Pig iron

• Forest products • Aluminium •

Project cargo/Heavy

lifts

• Containers • Loose bulk • Pitch

coke

• General (e.g. bags/ drums) • Scrap steel

and granite Richards Bay Liquid Bulk Terminal

Richard Bay has a single dedicated liquid bulk berth

(Berth 209) which handled 1,129 051 tons of bulk liquids

in 2005/2006 The maximum vessel size permitted alongside

berth 209 is 225 metres LOA (lenth overall), 12,5 metres

draft or not more than 67 000 dwt.

Berths 209 along with berths 301 and 302, also have bunker

points. Bunkers can also be provided by a bunker barge at

all berths. Other Private OperatorsSasol Agri

Operator: Sasol Agri.

Commodity: Phosphoric acid.

Storage: In 4 tanks of 11,000 tons capacity.

Equipment: Pipeline operation (connect pipes to

tankers).

Berths: 608/ 609 - permissible drafts of 13,5m and

14,0m.

Land surface Area: 1,309 hectares. Marine ServicesA fully equipped diving service is available for ship

inspection. Ship repair is undertaken at the quayside

(usually the small craft berth), as the port currently has

no ship repair facilities, although a large facility is

being planned. A dry or floating dock is under

consideration.

Cruise ships make use of either the small craft berth or

one of the normal cargo-handling berths, depending on the

size of the ship. There is a modern marina at the small

craft basin. Water sports and recreational facilities are

available in the harbour at reserved places. Marine CraftRichards Bay operates a fleet of five tugs owned and

operated by the Transnet National Ports Authority (TNPA).

Four of

these are identical Voith Schneider-type craft built in

1974 with 43-ton bollard pull - Ibakhu (formerly JH

Botha), Indwa (formerly Jan Haywood), Uhuva (ex W Marshall

Clarke), and Uzavolo (formerly RH Tarpey). Two are for

sale. The fifth tug is a Voith Schneider-type named

Indlazi, built in 2002 with a bollard pull of about 55

tons. The tugs are maintained to SAMSA class 8 standard,

and are equipped for fire fighting and salvage.

The port also employs a twin-screw diesel work boat/tug of

the Tern class named Swift Tern, which has a bollard pull

of 19 tons. This vessel entered service at Richards Bay in

September 1998, and also provides pilotage transfers when

necessary.

A pilot service was provided by an Agusta A109 K2 'HPS'

twin-engine 8-seat helicopter which was operated by

Balmoral Maintenance Services. The aircraft based at

Richards Bay, however, was involved in an accident and has

yet to be replaced. In the meantime, two diesel-powered

pilot boats (named Ivubu and Ballito) are in service.

Dredging is performed by the TNPA on an continual basis

inside the port and immediately outside the entrance,

using a trail suction hopper dredger named Ingwenya

(formerly HR Moffatt). The port operates a single screw

launch named Piet-my-Vrou.

The NSRI base at Richards Bay includes a deep-sea rescue

craft. General

• Repairs - Facilities exist for most types of

repair work to vessels. No dry-dock available. Diving and

engineering companies available.

• Dock ship repair facilities - No dry-dock

available.

LinkagesA dedicated railway line connects the port with Mpumalanga

and Gauteng, and was designed specifically to handle the

majority of South Afroca's coal exports. Other rail links

connect Richards Bay with Durban in the south, and

Swaziland and Mpumalanga to the north. There is an

adequate road system to Gauteng, Swaziland, Mozambique and

Mpumalanga, and an excellent road south to Durban. The

port has extensive rail and conveyor belt systems,

servicing the berths from nearby factories and plants.

Port VolumesThe table below illustrates the tonnage handled in

2005/2006 versus the actual capacity of the terminals.

In the calender year of 2006, the Port of Richards Bay

handled a total of 1575 vessels. The total volume handled

was 86,319,200 tons, of which 81,384,838 tons were bulk

cargo and 4,934,362 tons breakbulk.

Exports amounted to 80,050,728 tons of which bulk

cargo made up 75,075,617 tons, coastwise 171,803 tons and

breakbulk 4,803,308 tons.

Imports amounted to 6,268,335 tons of which

breakbulk made up 130,917 tons and bulk cargo 6,137,418

tons. Of the bulk cargo landed, 316,850 tons were

coastal. Transhipment of cargo totalled only 137 tons.

For the 2006/07 financial year, 63,540,607 tons of coal,

3,728,948 tons of woodchips and 2,798,517 tons of ferroy-

alloys were exported. Most of the imports were made up of

aluminium (1,560,662 tons) and coal (1,661,533 tons).

|

|